Long axis

Number of views:

1000

Key words:

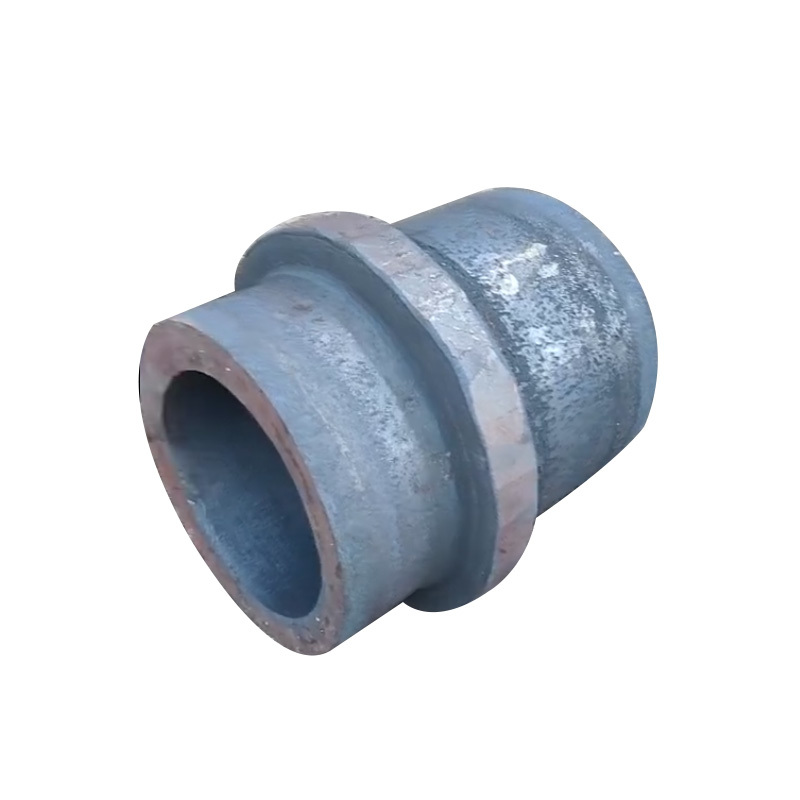

Flange forgings

Classification:

Introduction

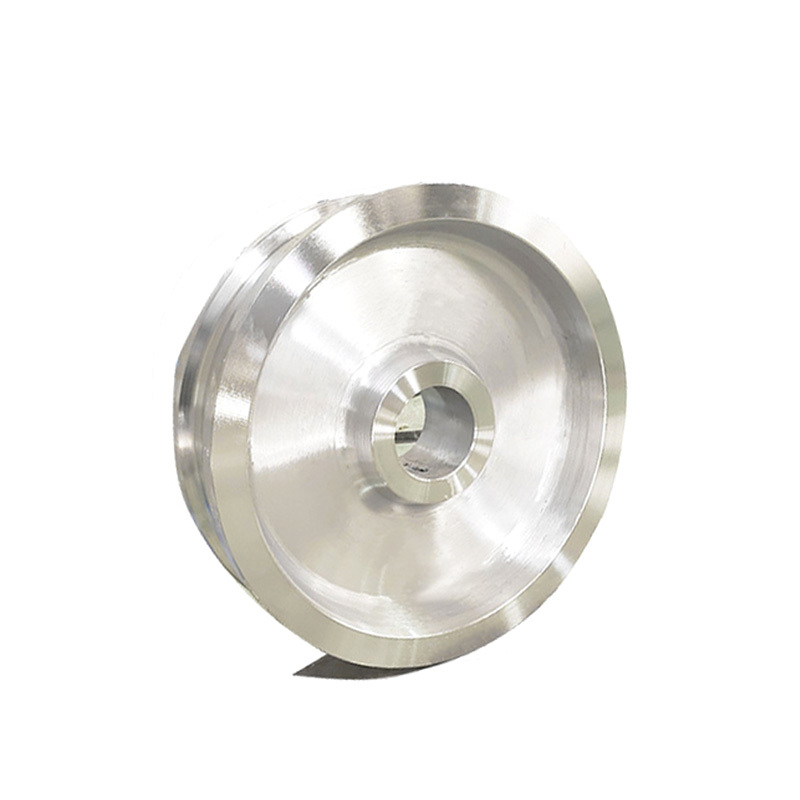

Long Shaft Forgings: Process, Applications, and Importance

I. Overview

Long shaft forgings are important mechanical components widely used in various industrial fields. They are mainly used to transmit power, motion, and control the operation of mechanical devices. Long shaft forgings are favored for their high strength, good wear resistance, and corrosion resistance.

II. Manufacturing Process

1. Material Selection: Long shaft forgings typically use high-quality steel as raw material to ensure their mechanical properties and durability.

2. Forging Process: By heating the steel to an appropriate temperature, plastic deformation is performed using a press or hammering to obtain the desired shape and size.

3. Heat Treatment: After forging, heat treatment is performed to improve the internal structure and properties of the material, enhancing its hardness and wear resistance.

4. Inspection and Testing: Strict inspection and testing are conducted on the forgings to ensure their quality meets standard requirements.

III. Characteristics and Advantages

1. High Strength: After forging and heat treatment, long shaft forgings exhibit excellent mechanical properties, capable of withstanding high loads.

2. Good Wear Resistance: The forgings undergo special treatment, providing outstanding wear resistance and extending their service life.

3. Corrosion Resistance: Made from high-quality materials, they have good corrosion resistance, suitable for various harsh environments.

4. High Precision: Advanced manufacturing processes ensure that the forgings have high precision and consistency.

IV. Applications

Long shaft forgings are widely used in energy, aerospace, transportation, petrochemical, and other fields. For example, in the energy sector, they are used in key components such as wind turbines and oil drilling platforms; in aerospace, they are used to manufacture parts for airplanes and rockets; in transportation, they are used to manufacture key components for high-speed trains and automobiles.

V. Importance

Long shaft forgings play a crucial role in various machines and equipment. They are key components that ensure the normal operation of equipment, and their performance and quality directly affect the performance and safety of the entire equipment. Therefore, manufacturing high-quality long shaft forgings is of great significance for ensuring the smooth progress of industrial production.

VI. Conclusion

In summary, long shaft forgings are important mechanical components with a wide range of applications. Understanding their manufacturing process, characteristics and advantages, and importance helps us better recognize and understand the role of this key component in industrial production. With the advancement of technology and industrial development, the demand for long shaft forgings will continue to grow, and the requirements for their quality and performance will also continue to increase.

Previous:

The next one:

Online consultation

* Please leave your phone number and we will contact you within 24 hours!

Related Products