Long neck flange

Number of views:

1000

Key words:

Flange forgings

Classification:

Introduction

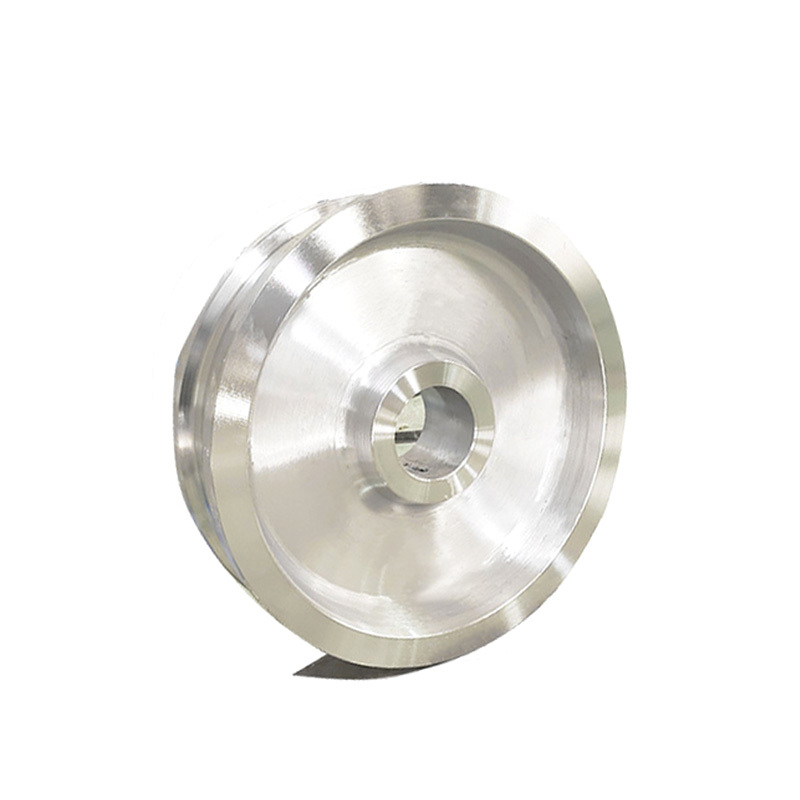

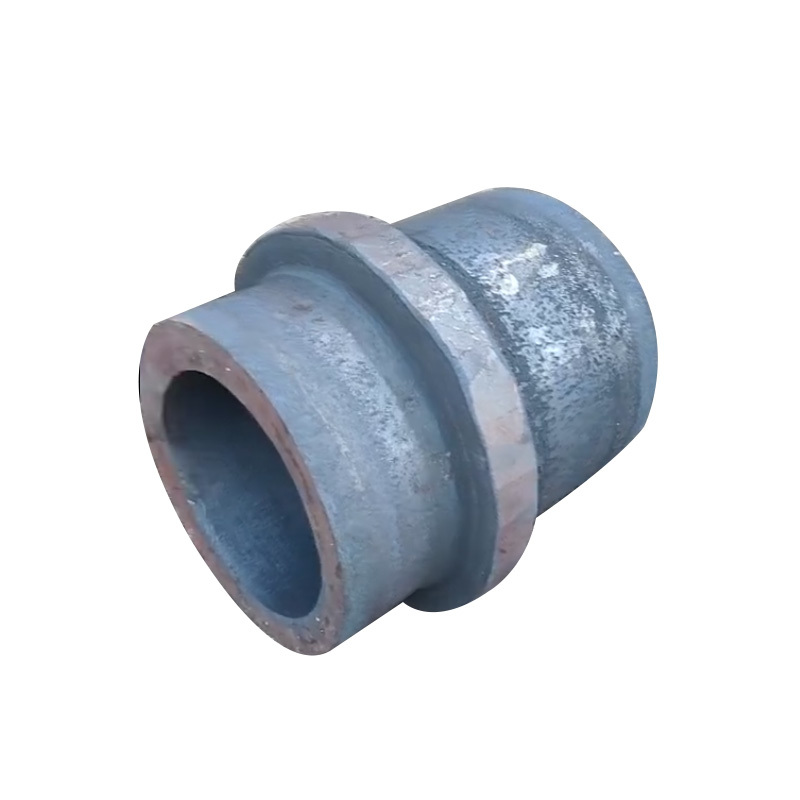

Long Neck Flange: An Important Connection Device

The long neck flange, as a connection device, is widely used in various industrial fields. Its basic structural feature is a long neck and flange plate, which provides higher stability and reliability during the connection process.

1. Basic Overview of Long Neck Flange

The long neck flange is a type of connecting pipe fitting, mainly composed of a neck, flange plate, and connecting bolts. Its length typically ranges from several tens of centimeters to several meters, depending on application requirements. The main materials for long neck flanges include carbon steel, stainless steel, and alloy steel, which have good corrosion resistance and mechanical properties.

2. Importance and Application Fields of Long Neck Flange

Long neck flanges have a wide range of applications in industries such as petroleum, chemical, electric power, and metallurgy. Their main function is to establish connections between pipelines or equipment, facilitating the transmission and exchange of media. Due to their advantages of easy connection, good sealing, and high pressure resistance, they are widely used in various high-temperature, high-pressure, and highly corrosive environments.

3. The Role and Significance of Long Neck Flange Length

The length of the long neck flange is of significant importance to its application. Firstly, an appropriate length ensures the stability and reliability of the flange connection, avoiding issues such as instability or leakage caused by a short neck. Secondly, the length can also adjust the spacing between pipelines or equipment to meet different installation needs. Additionally, the length can provide shock absorption and buffering, enhancing the overall safety of the system.

4. Selection and Considerations for Long Neck Flange

When selecting a long neck flange, factors such as material, pressure rating, and size need to be considered. At the same time, suitable sealing elements and fasteners should be chosen based on the actual application environment. During installation, attention should be paid to the alignment of the flange, control of fastening force, and protection of the sealing surface.

In summary, the long neck flange, as an important connection device, has a wide range of applications in various industrial fields. Its length not only ensures the stability and reliability of the connection but also provides certain adjustment and buffering functions. Various factors need to be fully considered during selection and installation to ensure its normal operation and service life.

Previous:

The next one:

Online consultation

* Please leave your phone number and we will contact you within 24 hours!

Related Products