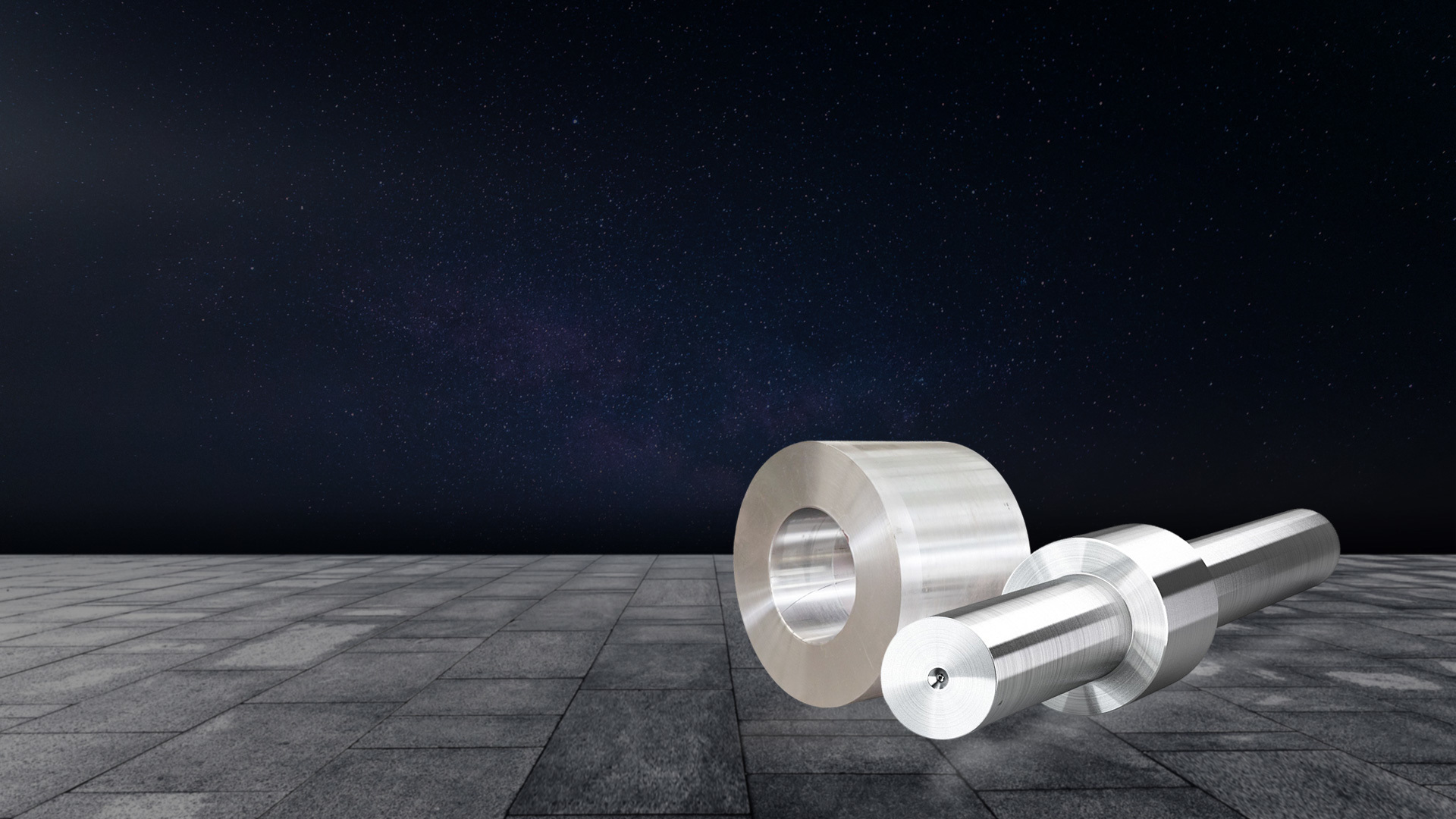

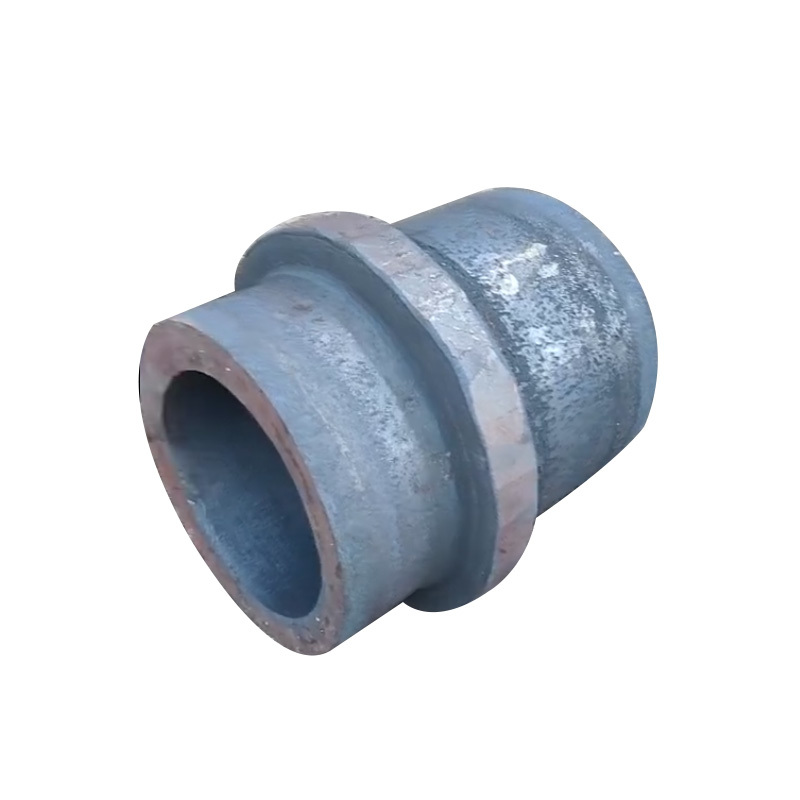

shaped forgings

Special-shaped forgings are characterized by their unique shape and precise dimensions, which can meet the special needs of different equipment and machinery.

Wind power flange

The wind power flange is a structural part connecting each section of the tower or the tower and the hub, and the hub and the blade are usually connected by bolts.

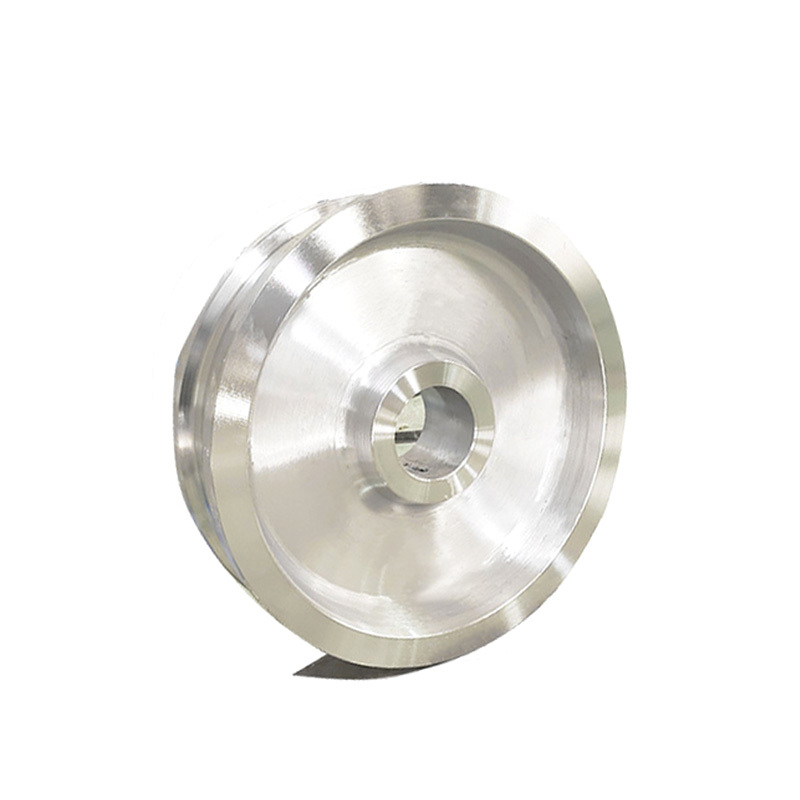

Ring

The ring length can be customized according to specific needs and designs to meet different functional and performance requirements.

Products

Dingxiang Shunjia Heavy Machinery Processing Co., Ltd. continues to explore in the industry, and its business covers the manufacture of general parts, metal chains and other metal products.

Source manufacturer

Preferred Materials

Fine workmanship

Advanced equipment

Quality Assurance

Peace of mind after-sales

ABOUT US

Dingxiang Shunjia Heavy Machinery Processing Co., Ltd.

Dingxiang Shunjia Heavy Machinery Processing Co., Ltd. continues to explore in the industry, and its business covers the manufacture of general parts, metal chains and other metal products. The company adheres to the value of "doing things only by thinking and people" and strives to reach a higher level. The enterprise adopts advanced technology and management mode to continuously improve product quality and production capacity. In such an industrial environment, the company continues to grow and contribute to the development of the local economy.

Advanced equipment

The enterprise adopts advanced technology and management mode to continuously improve product quality and production capacity.

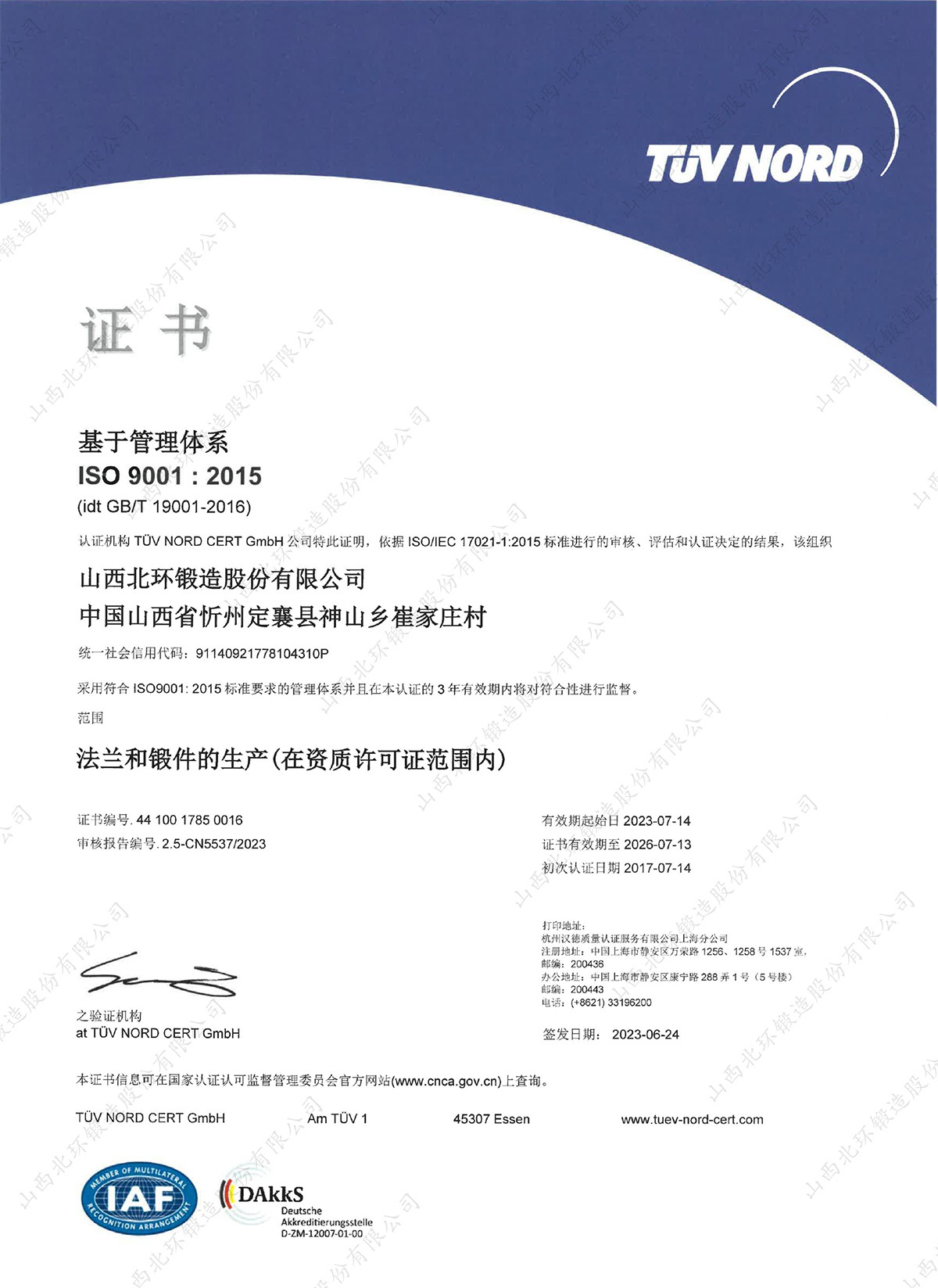

Strict quality inspection

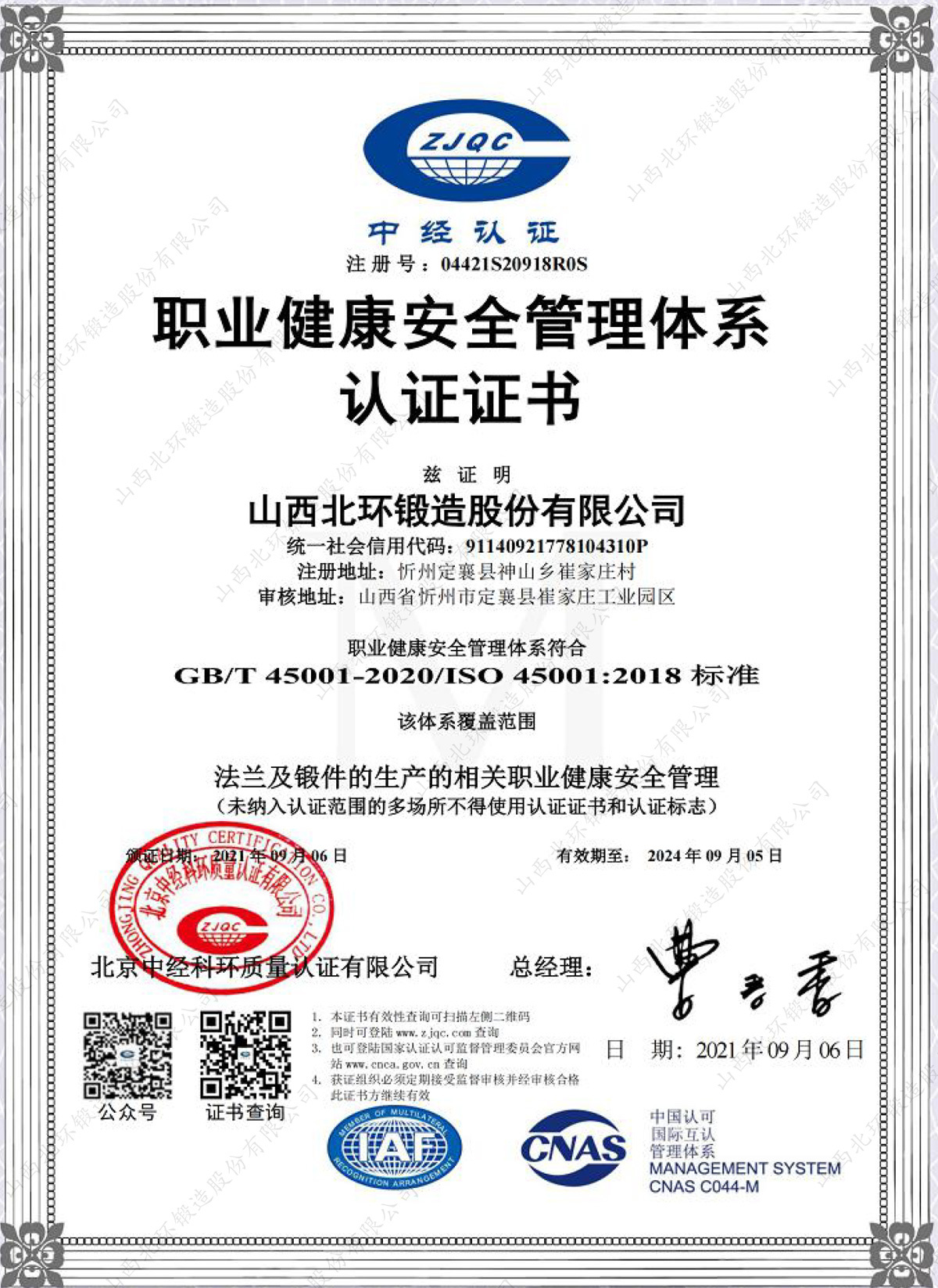

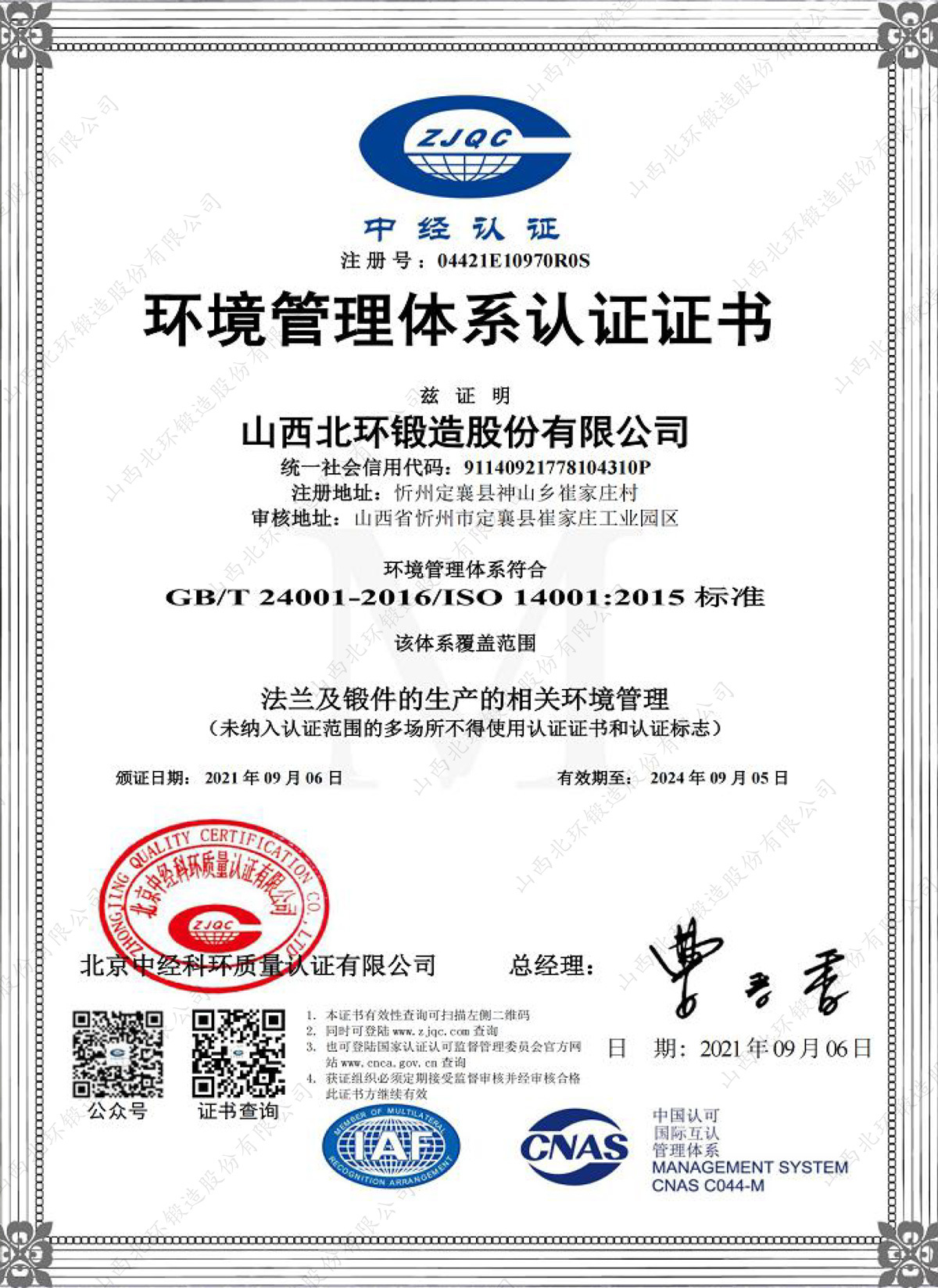

We have obtained a number of management system certificates.

Process flow

Dingxiang Shunjia Heavy Machinery Processing Co., Ltd. has a rigorous and efficient process to ensure high quality and excellent performance of products.

Procurement and inspection of raw materials

The company purchases high-quality raw materials from reliable suppliers, such as various types of metal materials.

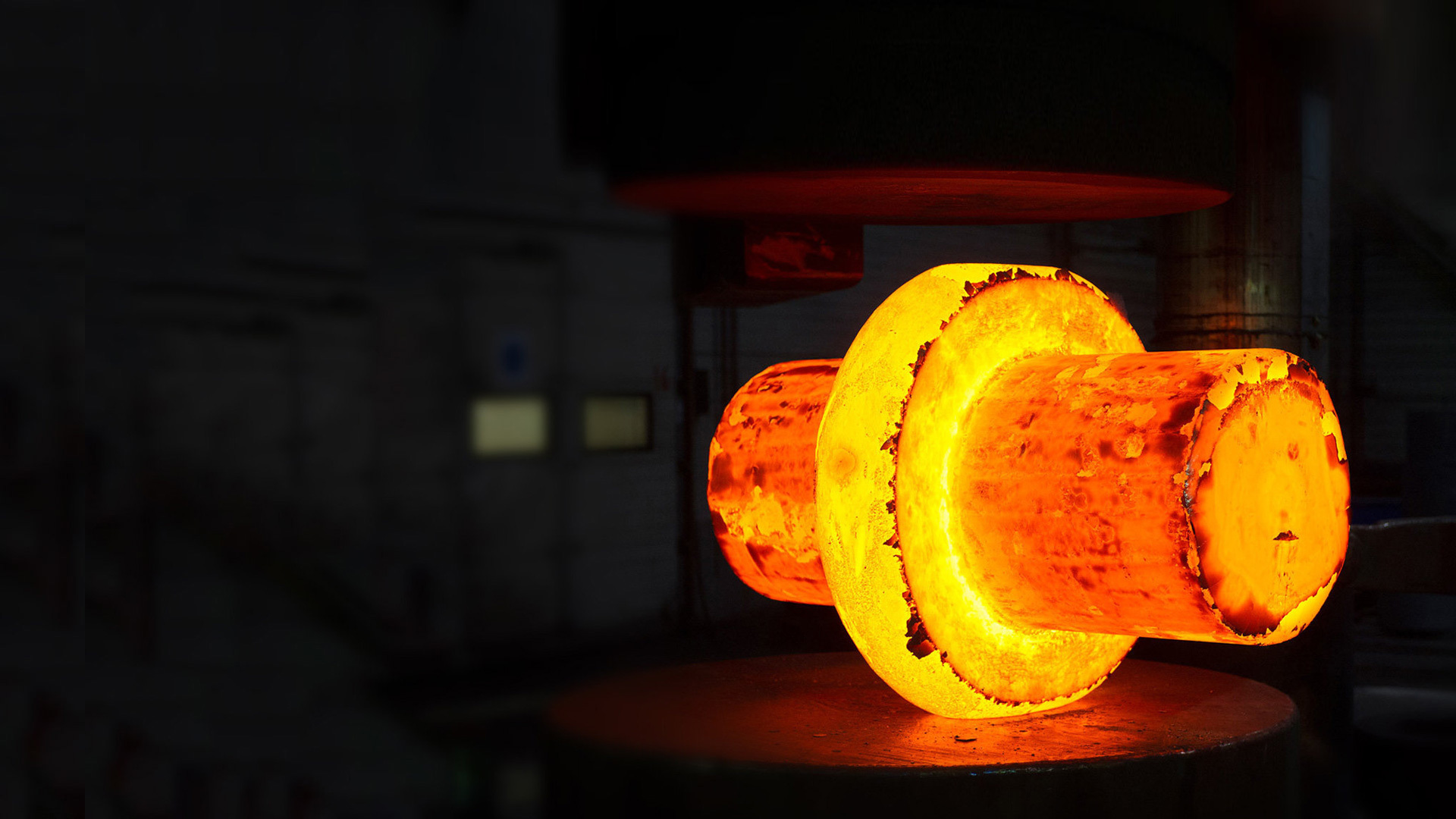

Forging link

In the forging process, the dimensional accuracy of the product is strictly controlled to ensure that the product meets the design requirements.

Machining

In the process of processing, continuous testing and adjustment are carried out to ensure stable product quality.

Metal surface treatment and heat treatment

Appropriate heat treatment is carried out on the product to improve the performance of metal materials and improve the hardness, strength and wear resistance of the product.

Quality Inspection and Packaging

Use suitable packaging materials and methods to protect the product from damage during transportation and storage.

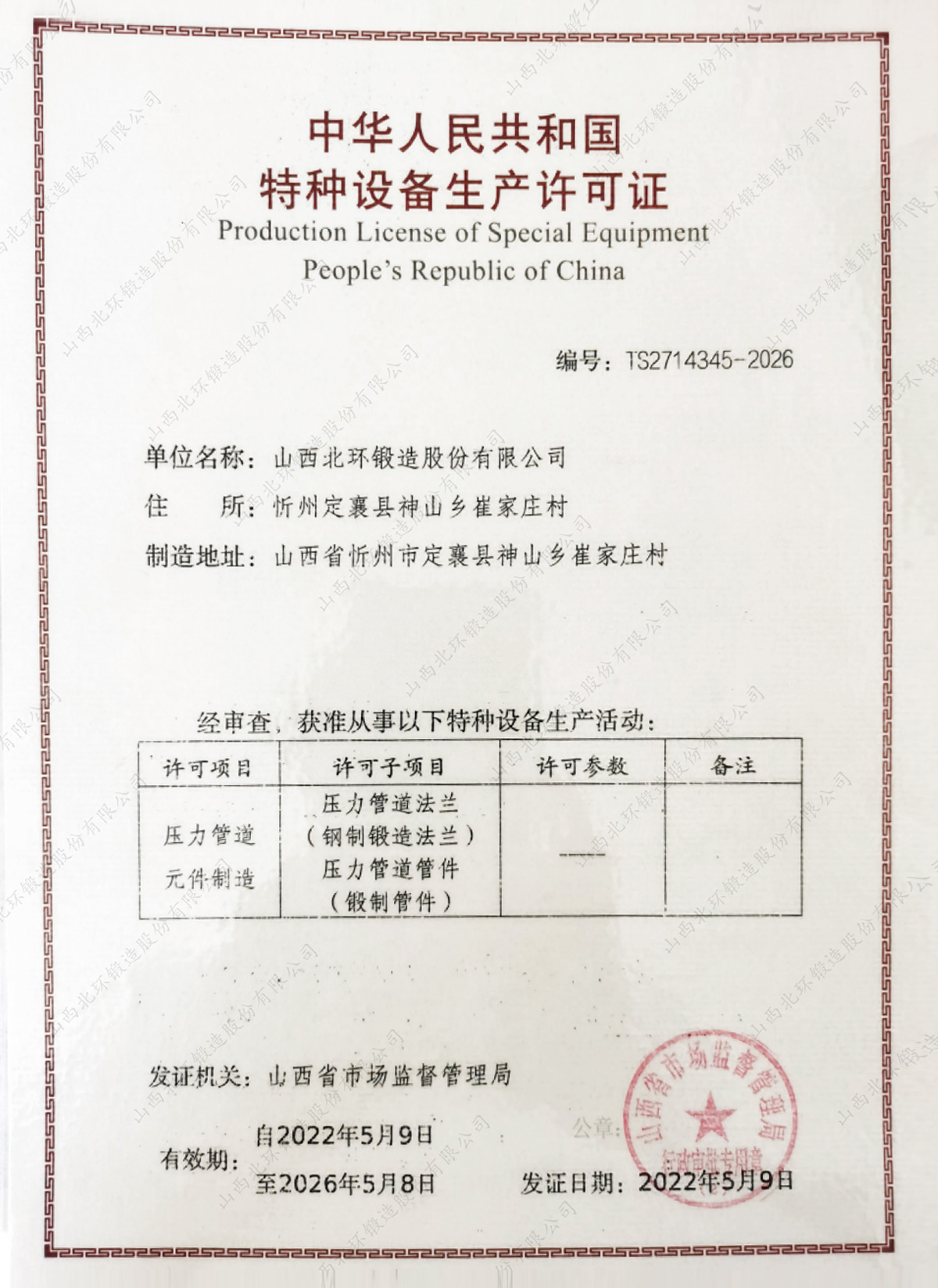

Qualification

Dingxiang Shunjia Heavy Machinery Processing Co., Ltd. continues to grow and develop in such an industrial environment, contributing to the development of the local economy.

Product Video

Whether it is metal products required in the construction field or mechanical parts in industrial production, Dingxiang Shunjia Heavy Machinery Processing Co., Ltd. has professional production capacity and technical strength.

News

Dingxiang Shunjia Heavy Machinery Processing Co., Ltd. welcomes friends from all over the world to inquire and negotiate

How to improve the hardness of carbon steel hot-pressed elbows

2023-03-07

What are the reasons for the price differences in stainless steel flanges?

2023-03-07

Characteristics of stainless steel flange forging equipment and applications

2023-03-07